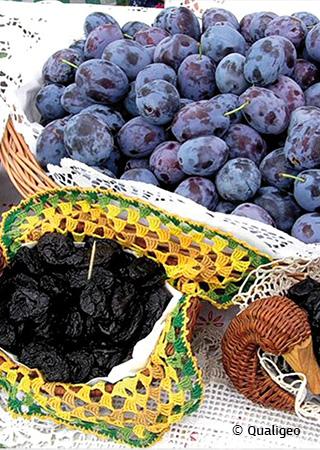

Characterised by a pulpy flesh and sticky blue-black skin, Suska sechlońska PGI is a prune with a slightly sweet taste and a smoky aroma.

The prunes owe their distinctive qualities to the traditional smoking and drying techniques used by local producers in the Małopolskie province of southern Poland.

Origins

Much of the story of Suska sechlońska PGI is revealed in its very name.

‘Suska’ denotes a dried and smoked plum, while the name ‘sechlońska’ comes from the village of Sechna in southern Poland, where the local tradition of smoking and drying plums originates. In fact, the name “Sechna” derives from the Polish word “suszenie”, which means “drying”, indicating the deep connection between the area and its culinary tradition.

While history does not record exactly when the tradition began, legend tells us that a local clergyman introduced plum-smoking to the area and encouraged his parishioners to take up the practice by spreading his knowledge and techniques.

The fruit kilns that are scattered across the landscape of the region act as monuments of the product’s history. The oldest of these kilns is over 100 years old. Although no longer operational, it shares the same structure and features as the kilns used today, proof that the production method has remained virtually unchanged in over a century. The area is dotted with as many as 677 kilns, all designed and constructed by the local people in a style adapted to the local terrain.

The drying and smoking tradition is not only built into the region’s landscape, but is also embedded in its culture. Local poets and songwriters need not look to the stars for inspiration, but rather find their muse in the humble smoked prune. The lyrics of one local song praise the town where the tradition began:

…Oj Sechna, Sechna ty skopciała wiosko,

gdyby nie suszarnie byłabyś stolicą…

(...Oh Sechna, smoke-blackened Sechna,

if it weren’t for the fruit kilns you would be the capital…)

The tradition is further celebrated by the Prune Festival (Święto Suszonej Śliwki), held in the village of Dobrociesz since 2001. Visitors to the region can also follow the ‘Prune Tourist Trail’, a route that winds between local plum orchards and fruit kilns.

As well attracting many tourists to its home region, Suska sechlońska PGI has also accumulated several accolades over the years, including a distinction in the 2000 Nasze Kulinarne Dziedzictwo (Our Cultural Heritage) competition, a prize at the Perła 2004 (Pearl 2004) competition for the best Polish regional food product, and first prize in the 2006 Małopolski Smak (Małopolskie Flavour) poll.

Further recognition came in 2010, when the European Commission established Suska sechlońska as a protected geographical indication (PGI), acknowledging the unique connection between the product and its area of origin.

Production

Suska sechlońska PGI is produced in four municipalities of the Małopolskie province: Laskowa, Iwkowa, Łososina Dolna and Żegocina.

The fruits used for Suska Sechlońska PGI are those of the European plum (prunus domestica L. ssp. domestica) and related varieties, such as Promis, Tolar, Nektawit, Valjevka and Stanley. These varieties are ideally suited to drying and smoking, as they are high in sugar and hold a relatively low water content. The fruit must also be of high quality; any plum with signs of rotting, damage, or contamination cannot be used.

Once plucked from the orchards, the plums are brought to the fruit kilns for drying and smoking.

Kilns are built into the landscape, sitting on a base of brick foundations and covered by a gabled roof. Each kiln contains at least one chamber, although some hold as many as five. Chambers are around 2 metres wide, upwards of 3.5 metres long, and are divided in half by a wooden barrier.

Beneath each chamber is a hearth, over which a wooden grid is placed. The grid comprises of adjacent knot-free sticks, 4 cm wide, 3 cm high and about 1 metre long. The sticks are arranged in such a way as to ensure the spontaneous circulation of smoke, allowing warm air to rise to a height of around 180 cm above the hearth.

Plums are spread across the grid in a layer 20-40 cm thick. Once a day, the producers use a special shovel to turn over the mass of drying plums.

The smoking and drying process lasts between 4 and 6 days, depending on the thickness of the plum layer. As smoke rises from the hearth, the temperature in the kiln rises to between 45°C and 60°C. The smoke dries and preserves the fruit, while also giving it a uniquely smoky colour, aroma and taste. During the drying process, juice oozes from the plums and envelops the fruit, adding a sweet aftertaste to the final product.

More information

Suska sechlońska PGI – legal specifications